Electrical transformers remain the unsung heroes of modern power distribution – these silent workhorses step voltage up and down with such reliability that we often forget their existence until something goes wrong. The global transformer market surpassed $40 billion in 2023 according to research by Global Market Insights, proving these electromagnetic devices form the backbone of our electrified civilization. Understanding their architecture, classifications, and operating principles matters not just for electrical engineers but for any facility manager specifying equipment or procurement officer evaluating suppliers like Ausin Pipeline Material & Equipment Co., Ltd., whose CNC core cutting machines enable precision manufacturing of transformer components.

The anatomy of a transformer

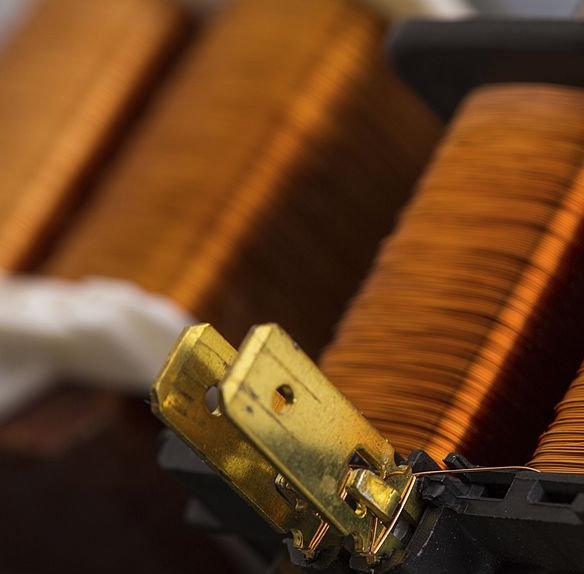

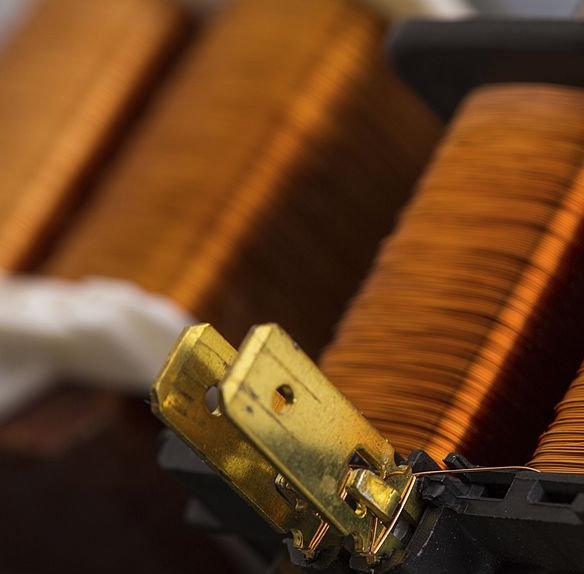

Every transformer shares three fundamental components working in electromagnetic harmony. The core, typically fabricated from grain-oriented silicon steel (CRGO) for its exceptional magnetic permeability, provides a controlled path for magnetic flux while minimizing energy-wasting eddy currents. Ausin's CRGO cutting machines produce these laminations with the precise 0.23mm to 0.30mm thickness required for optimal performance. Windings – either concentric cylinders or interleaved discs of copper/aluminum conductors – create the electromagnetic coupling, with the turns ratio between primary and secondary coils determining the voltage transformation. Insulation materials like kraft paper or synthetic polymers prevent winding shorts while withstanding operational temperatures up to 105°C in dry-type units. The often-overlooked conservator tank in oil-filled transformers accommodates thermal expansion of dielectric fluid, demonstrating how even "passive" components play active roles in reliability.

Four major transformer categories in industrial applications

Classification by voltage transformation reveals power transformers as the heavy lifters, handling 33kV+ transmissions with efficiencies exceeding 99%. These behemoths are constructed using Ausin's advanced transformer forming machine technology, specifically their rectangular open core automatic models, to achieve the stringent stacking tolerances that minimize no-load losses. Distribution transformers (220V-33kV) bring power to end users, while instrument transformers provide safe measurement of high voltages/currents – the CT's wound core construction benefits from precision cutting on Ausin's slitting lines. Isolation transformers, though technically providing 1:1 ratios, prove indispensable for sensitive equipment protection, with their interleaved winding configurations demanding exacting layering during manufacturing. The International Electrotechnical Commission's IEC 60076 standards govern all four types, mandating performance characteristics that begin with material selection and core fabrication quality.

The mechanism of electromagnetic induction

Faraday's Law of Induction (1831) still governs every transformer's operation today, though modern CAD simulations now optimize what was once trial-and-error design. When AC flows through the primary winding, it generates a time-varying magnetic field that couples to the secondary winding through the core. This induced EMF follows the simple yet profound relationship V₁/V₂ = N₁/N₂ – a formula so elegant that even Tesla would approve. Modern designs enhance this basic principle with stepped-lap joints cut by CNC machines to reduce flux leakage, while amorphous metal cores (now being adopted in high-efficiency transformers) demonstrate how material science continues refining this 19th-century invention. The transformer's apparent simplicity belies the precision required in components – a core gap irregularity as small as 0.1mm can increase audible noise by 15dB, justifying investment in precision cutting equipment like Ausin's systems.

Core versus windings: How do these components differ functionally?

The core-winding duality represents the yin-yang of transformer design: one handles magnetic flux, the other electric current. CRGO cores must balance competing needs – high silicon content (3%) reduces eddy currents but increases brittleness during cutting, requiring Ausin's specialized CNC machines to achieve clean edges. Windings, conversely, prioritize conductivity and thermal durability, with aluminum now displacing copper in cost-sensitive applications despite its 61% lower conductivity. Contemporary designs optimize this partnership through computational modeling – ANSYS Maxwell simulations can predict how a 0.05mm variation in lamination thickness affects the core loss curve, enabling Ausin's clients to tune their cutting parameters for specific performance targets. This synergy explains why transformer OEMs increasingly source complete core processing lines integrating cutting, stacking, and winding from single suppliers.

References

International Electrotechnical Commission. (2023). IEC 60076-1: Power transformers – General.

Global Market Insights. (2023). Transformer Market Size Report, 2023-2032.

ABB Technical Guide. (2022). Dry-Type Transformer Specifications.

IEEE Power & Energy Society. (2021). TP1-2018 Guide for Transformer Loss Measurement.

MIT Energy Initiative. (2022). Next-Generation Transformer Materials Study.

Ausin Pipeline Equipment. (2023). CRGO Core Cutting Technical Manual.

Fraunhofer Institute. (2023). Amorphous Core Transformers: Performance Benchmarks.

US Department of Energy. (2022). DOE 2023 Transformer Efficiency Standards.

Daniel Richardson

Senior Power Systems Engineer (PE)

With 18 years dedicated to electrical infrastructure design, I specialize in advanced industrial power quality solutions. As a certified Professional Engineer, I have successfully led high-stakes substation projects, serving major Fortune 500 clients across Asia-Pacific.

English

English